Pitch deck / video / pictures, click here.

Many cities want to clean and shut down fossil fuel-based power plants and heating systems.

Clean alternatives have been sought for decades and no solution has been found.

We urgently need to find a new innovative, preferably system-level solution to the problem.

This solution is an example of what Solixi and its team offer cities;

Helsinki Energy Challenge scores, released 16.3.2021:

ABCD for clean heating in Helsinki (video, click here)

Team score 3,0 Plan score 5,0 Total 8,0

Of the 252 applications, Solixi was among the top 26.

Jury comments:

Team with strong experience relevant to the proposed solution, and, in the energy sector or in developing or implementing energy technologies or systems. The diversity of relevant expertise strong.

Proposed plan good for the purpose of this competition (in terms of most of the evaluation criteria); however, implementation feasibility, costs and capacity of the system are only moderately described and not all risks impacting feasibility are taken into account. Due to this, the plan did not qualify to the final round.

Solixi CEO’s comment: There was no space for more numbers and text in the application form (texts copied below). They have simply been removed due to lack of space.

All risks, details, prototypes etc. – Solixi include a dozen innovative product lines – are described at solixi.com/products

and in

EU Innovation Fund Large Scale Projects

material what contains more than 50 pages;

SolixiIF_BusinessPlan.pdf

SolixiIF_GHG.xlsx

SolixiIF_PartB.pdf

SolixiIF_FeasibilityStudy.pdf

SolixiIF_ImplementationPlan.pdf

Heating costs for the whole of Helsinki electricity 38M € + maintenance (all buildings).

Less than 70 € per person per year. No emissions. Including cooling.

The cheapest solution to the challenge is below?

__________________

The plan for Helsinki in brief

Solixi equalise seasons and consumption

The difference between the average outdoor temperature and the indoor air at 20 ° C is usually only a few degrees.

For clean heating we need;

- Building specific big 1-15 MWh water boilers / tank containers to balance consumption peaks and to charge the soil storage

- Giant TWh scale rechargeable soil heat storages to eliminate seasonal variations

- Low temperature district heating network to transfer heat in/out/between water boilers and soil storages

- Internet Controllers to automate heat flows and heat- & water pumps running times

- Concentrated Solar Power to produce hot 80-120°C water

- A little electricity for heat pumps; fluctuating wind / solar power

Great part of the heat is generated simply by pumping water and heat between the buildings and the soil heat storage. Intensive heat pump and solar charging in summer. Soil temp. reaches 60-90 ° C in autumn and drops to 40 ° C after winter (when more heating than cooling is needed).

Rest of the heat is produced locally in smart water tanks; optimal temperatures and high COP water-to-water and water-to-air heat pumps and solar.

Both warm and cold water are stored simultaneously in insulated underground tank containers.

2-40-80-120 ° C water is used directly for heating and cooling.

- Heat pumps are ON when affordable power is available

- Small low-cost devices because consumption peaks are balanced

- Transport and storage of coal, gas and wood is unnecessary, no chimneys

- Small underground space requirement

- Massive local and seasonal heat storages secures the heating of buildings

Efficiency is improved in buildings, when possible, with low temperature heaters such as floor heating, low temperature radiators, heat recovery units, cooling panels, intelligent IoT room thermostats

and

integrated Solixi devices, such as purpose-built IoT Controllers with weather and energy price forecasts and Solar Concentrators.

Investment is approximately € 2,000 and costs € 100 per year per inhabitant.

EaaS, Energy as a Service.

_________ 1. _________

Climate impact

Solixi is 100% clean urban heating and cooling system

without burning any fuel, no CO2 or other emissions.

Solixi is installed one block or building at a time and operates flexibly as part of district heating network and system. Local energy company is the operator and the heat is transferred to the building through a heat exchanger as before. The Solixi water tanks can also be connected to housing company’s heat pumps, a heat recovery unit, already installed geothermal systems and other equipment which are connected to a regular water boiler.

2 / 7,5 TWh

Calculations are dimensioned to 2 TWh, to replace one coal power plant heat production

and in italics

for the entire heating of the city 7,5 TWh

By installing Solixi in almost all building blocks and scaling the capacity of the soil thermal storage capacity, gas heating power plants and a bio heat power plants can also be replaced.

Cold winter days peak power:

Older buildings in particular need high temperatures of 90 ° C and high power from the DH network in severe frosts.

The middle area of the soil heat storage can be saved these days at a temperature of 80-90 ° C.

If the building has Solixi water tanks (1-15MWh), these will be fully charged before the peak, so there is enough heat without DH for hours or days.

When these are not enough, with peak boilers it is easy to raise the DH temperature up to 115 ° C. The amount of emissions is affected by the length of the cold time period and the number of buildings where Solixi is installed.

When the Solixi system is widely in use, no burners or any fuels are needed at all in a normal year.

_________ 2. __________

Impact on natural resources and energy resources

The heating and cooling is completely electrified

An average electricity power of 37 /148 MW;

- varying wind power

- solar power

- or any clean power combination

- Heat pumps COP 6, 222 / 855 MW heat

Building-specific water boilers / tanks,

placed next to the building; underground, a few parking slots, behind a garbage garage etc.

3 bar pressure, max. temp. 125°C, three models;

200 /1000 pieces x 15 MWh; 3 x 40 feet tank containers

- Water volume 3×50=150m³

- Width 3 m, length 14 m, height 9 m with thick insulation

- 150-500 residences, 500-1500 occupants

- Heat pumps; water-to-water and water-to-air total power 200kW

- DH heat exchanger to transfer heat in/out of the water boiler

- Rooftop solar collectors or CSP (Concentrated Solar Power) when possible

350 /1000 pieces x 6 MWh; 3 x 20 feet tank containers

- Water volume 3×20=60m³

- 3 x 7 x 9 m

- 100-500 occupants

- Heat pumps; water-to-water and water-to-air total power 80kW

- DH heat exchanger to transfer heat in/out of the water boiler + Rooftop solar collectors or CSP (Concentrated Solar Power) when possible300 /1000 pieces x 1 MWh

- Water volume 13,5 m³

- 2,5 x 2,5 x 4,5 m

- 30-100 occupants

- Heat pumps; water-to-water and water-to-air total power 10kW

- DH + solar

550 / 2300 GWh soil storage(s) and CSP solar thermal power plant(s)

- Area and volume 300x300x300m / 600x600x300m

- 5625 /22.500 300m deep geothermal wells, distance 3-5m

- Area size about one / four; 300x300m; expansion margin up to 2,3 TWh (for the entire heating of Helsinki) capacity, space for waste heat collection from peripheral areas and stormwater management

- On the top insulation and 90.000 / 360.000 m² solar thermal collector field / CSP

- Connected into low temp. DH network

- Located in locations and fields where the soil is suitable and there is enough space.

_________ 3. __________

Cost impact

Total investment

296 M€ to replace one coal power plant

or

all heating in city 1.162 M€

In building blocks 215 / 858 M€

- Water tanks and pipes 33 / 129 M€

- Heat Pumps 500MW heat power, water-to-water and water-to-air, Controllers, heat exchangers etc.; 108 / 440 M€

- Rooftop solar, when possible CSP water heating; 8 / 32 M€

- Installation underground and on roofs; 66 / 257 M€

The soil heat storage 88 M€ to replace coal power plant

- 300x300m area, 550GWh, 5 625 pc. 300m deep wells; 51 M€

- Concentrated Solar Power plant area 300x300m; 31 M€

- Insulation 300x300m and stormwater drainage etc. infra 7M€

OR

The soil heat storage 322 M€ for all heating of the city

- 600x600m area, 2,3 TWh, 22.500 pc. 300m deep wells; 202 M€

- Concentrated Solar Power plant area 600x600m; 90 M€

- Insulation 600x600m and stormwater drainage etc. infra 30 M€

Prices VAT 0%. The price of the land or the connection to the district heating network is not included in the price.

When purchases and installations are made in large quantities, prices are likely to fall by 10-40%.

Annual electricity costs 10 / 38 M€

- 37 / 148 MW average and 80 / 300 MW max power for heat pumps

- 316 128 / 1 260 240 MWh annual need for electricity

- Electricity price 30 € / MWh – Heat pumps are used for approximately two weeks a month when electricity is cheap and COP is high

- The power grid may need to be slightly strengthened, costs are not included

________ 4. __________

Implementation schedule

Implementation in 4 / 6 years

First year for planning, finishing the prototypes and controller software, purchasing and delivery delays.

Second year, installation in 50 buildings and drilling of 2000 soil heat storage wells.

3 / 4 years installation of 40% of the buildings and drilling the rest of the 300m deep geothermal wells.

4 / 6 years installation of 60% of the buildings and CSP solar on the top of the geothermal soil heat storage.

A. No risk, when using standard devices

Water boilers are slightly modified tank containers. Manufacturing, transportation and usage according to ISO standards do not include risks. Similar containers have been manufactured and are now in use for about half a million. Insulated walls from normal building materials.

300m deep geothermal well is a standard.

Suitable heat pumps are on the market and widely used. There are dozens of potential suppliers.

Suitable solar heat collectors are on the market and are widely used. There are dozens of potential suppliers.

Commonly used heat exchangers, controllers and installation methods can be used.

B. Risk, when using purpose-built, optimal and integrated devices

- AI & IoT Controllers and software to automate precise timing and temperature control (TRL 6-7)

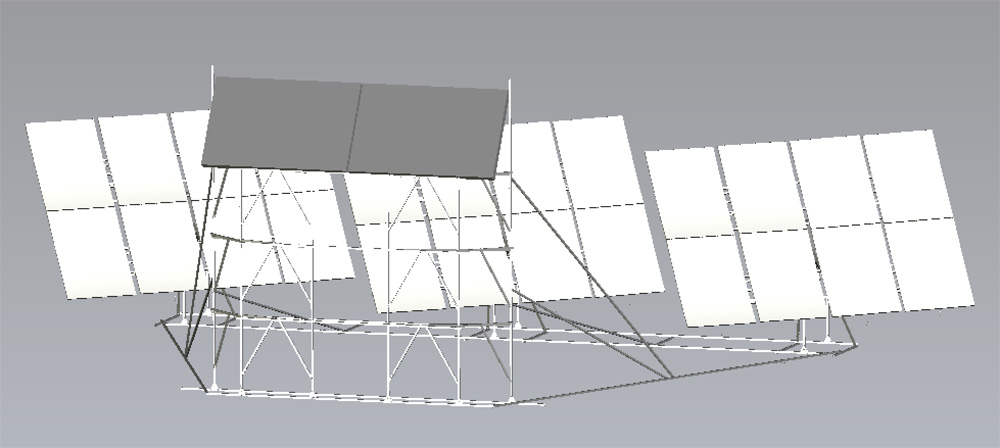

- Patented Solar Concentrators (TRL 6-7)

- Devices like heat pumps, water pumps, temperature sensors and electric resistors (TRL 6-7)

- Security, off-grid mode, seasonal and daytime mode-sets to simplify remote control in different buildings etc. (TRL 6-7)

have been tested in prototypes in 2013-2020 (TRL 6-7).

With B. option, costs are reduced, savings are greater and security, efficiency and usage better.

_________ 5. __________

Implementation feasibility

Solixi systems consist of products already in the market or technology readiness level is high.

Building specific 6 and 15 MWh water tanks are modified standard ISO type 1CC / 22T6 tank containers, smaller 1MWh fits into a sea container. There are pipes / pushes from which water flows in and out, to which manifolds and ball valves are connected. Plug and Play. There are pipe holes for vertical flow of water to the top and bottom. Drawings have been made but full implementation has not yet been done. Control by (Solixi) controller is sufficient. A water tank outdoors is harmless even in the event of a leak, insulated walls are not hot. Pressure control is done by an automatic Compressor.

The risks are in minimal, routine work for a person skilled in the art.

The depth of ordinary geothermal wells is 100-300 m. 300 m is sufficient in Solixi. Deeper, more expensive and riskier wells have also been drilled, but they are not needed because there is no need to get “fossil or geothermal heat” from the soil. Soil is charged as much as heat is consumed. Lifespan is eternal.

CSP-Concentrated Solar Power plants have been built at lower latitudes. In Helsinki, the sun never shines zenith. Since 2013, three CSP prototypes have been made for higher latitudes, rooftop and the ground installations. Above 100 ° C was reached daily even in winter. Solixi Solar Concentrators are almost ready for series production.

Parts and devices are on the market. There are plenty of sellers and manufacturers.

Procurement can start together with the completion of R&D activities. (TRL 6-7).

_________ 6. __________

Reliability and security of supply

Existing energy systems and networks depend on continuous energy production and transmission. A power failure or a pipe break in the district heating network will cut off all heating immediately.

The Solixi system is very robust and security of supply is guaranteed in many ways

- When batteries and solar energy guarantee the low electricity consumption of water pumps, heat is transferred to the building from building-specific water tanks despite external disturbances

- Heat is obtained in gigawatt hours from a geothermal storage only by pumping water

- Damage to the district heating network does not interrupt heat transfer from the building specific storage

- Local heat production, solar and/or heat pumps can operate locally partially or completely without external energy, even if the big building specific heat storage is empty

- The critical part of the system is a water pump, which can be advantageously duplicated

The Solixi system has several features that improve the reliability of heating in addition to city’s current heating system.

Low heat loss, long life cycle, known technology and good compatibility as part of security

- Heat losses decrease in bigger storages – in practise no heat losses in huge Solixi storages

- Detected heat leaks can be blocked or waste heat recycled

- District heating network temperatures and also heat losses are smaller than currently

- Tank containers lifespan is over 50 years, excellent maintenance service

- Heat wells lifespan is over 50 years

- Normal heat pump and pipe renovation is made easy, the system is plug and play.

- One control room can be anywhere, one Solixi Controller for all devices and heat storages

- Easy connection to any smart city application

- All devices have been tested and are known in the art

_________ 7. _________

Capacity

Solixi is a 100% emission free solution which consists of new and unique innovations.

Building-specific water boilers / tanks

- Capacity in megawatt hours MWh, not kilowatt hours kWh (when tank is indoors)

- Volume in cubic metres, not litres

- Temperatures change between 0-120 °C instead of traditional 20-70 °C

- Three compartments, stores hot and cold simultaneously (doubles HP’s COP)

- Minimal heat losses; thick uniform insulation, big size close to the building

- Quick and trouble-free installation underground

- Safe, no water or steam damage indoors

- Containers logistics, manufacturing, services

Patented Solar Concentrator (CSP);

- Warms always when the sun is shining, hot even in the winter

- Even production from morning to evening year round

- Even a short glimmer of sun warms up

- The only controllable solar collector, on/off, control of the produced temperature

- Turning mirrors (heat) & PV panels (electricity) always towards the sun

- Over the shadows on top of the roof top

- Towards south independently of the shape of the roof

- Little need to clean up, does not collect snow, dust or garbage

- Several sizes and models

- Easy and fast assembly, can be dispersed into parts

Automatic Controllers

The system functions under the steering of IoT controllers. Controllers control CSP mirrors and solar heat and optimize charging and discharging times as well as water pump powers and running times in different parts of the system.

The result is an increase in capacity to a whole new level, which makes it possible to load the massive TWh-Scale soil thermal storage at very low costs.

Heat is produced and stored when energy is available for free or it is cheap.

Heat storages are discharged when energy is expensive and during peak consumption.

Heat is pumped from storages reliably and virtually free of charge.

__________________

ASSUMPTIONS

The assumption is that the Solixi system as a whole is understood without omitting or adding essential components.

- Low temperature (30-60 ° C) district heating network requires site-specific and local storage capacity and energy production

- Local heat production allows for lower temperatures in DH and massive transfer of excess summer heat to a giant seasonal storage

- The efficiency of heat pumps (COP) is much better when heating takes place mainly in summer

- Smaller devices are sufficient because local storage capacity eliminates consumption peaks

- Low price electricity times can be utilized and cost efficiencies are continuously optimized using IoT Controllers

- Giant soil heat storage is vital to eliminate seasonal variations

- The IoT Controlleres are vital for system integration, monitoring and control

- CSP Solar Concentrators are needed to increase the heat generated by heat pumps to the higher temperatures required in winter (80 – 100 ° C)

- Savings, zero emissions and security can only be achieved when the entire system is dimensioned and designed as a whole

Any changes in sizing, location or temperatures will affect all parts of the system.